<< back to main menu <<

MODEL TMF - TWIN MOTOR FEEDERS - PAN & GRIZZLY VIBRATING FEEDERS

Heavy Duty

QUICK

FACTS

|

Vibrating Feeder (pan feeder) supplied to an OEM manufacturer of scrap processing equipment, used in an auto- mobile materials reclaiming operation. Trough is lined with 5/8" thick UHMW Polyurethane. |

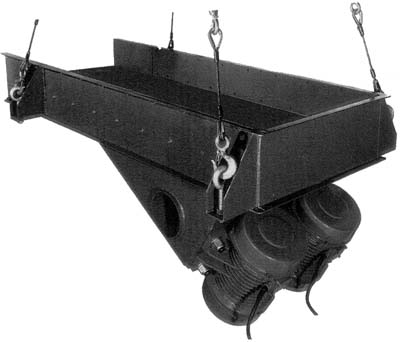

MODEL TMF-3072 twin motor vibrating feeder with overhead coil spring suspension mounting. Trough is 30" wide × 72" long with replaceable abrasive resistant liners. |

Model TMF-1248-660-4-(2)S

with |

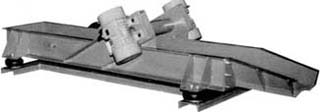

Low Profile Model TMF-1878-1320-4-(2) twin motor feeder with airmount isolation. |

PRINCIPLES OF OPERATION

Model TMF Twin

Motor Vibrating Feeders ( Pan and Grizzly Feeders ) are designed to convey product by creating a linear straightline

motion. Two counter-rotating motors provide the linear

(push-pull) action required.

As the AC motors counter-rotate, the side forces

cancel out and the linear forces are combined. With the motors properly

attached and located on a rigidized trough suitable for the forces being

exerted, and also suspended on isolation springs, the conveyance action is

quiet and positive. No belts are required. The synchronized motors provide a

semi-balanced design which eliminates the uncontrolled bouncing at shut down.

Final motors selected can be either 1800, 1200 or 900 RPM, depending upon

amplitude required. Final motor horsepower selected is a function of trough

weight and TPH capacity required.

All motors are continuous duty rated at

maximum force. Grease fittings and heavy duty roller bearings are supplied on

all 900 and 1200 RPM motors. 1800 RPM motors are factory grease packed and

furnished with sealed ball bearings.

Best Process Solutions, Inc.

1071 Industrial Parkway North

Brunswick, Ohio 44212

Phone: 330-220-1440 • Fax: 330-220-1447

© 2016. All rights reserved.