<< back to main menu <<

MODEL TMC - TWIN MOTOR VIBRATORY CONVEYORS

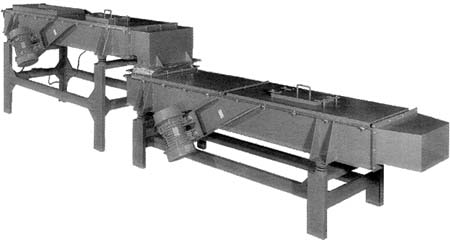

Three-Section Model TMC-24120-5280-6-(2) 24" wide × 30 ft. long overall vibrating conveyor. Hi-temperature design for conveying hot aluminum scrap metals to a furnace. Pan is designed with multiple sections for expansion. |

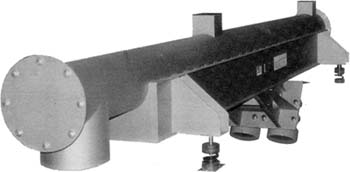

Model TMC-T-8-144-1980-6-(2) twin motor vibrating conveyor with 8" dia. × 12 ft. long tubular trough. |

Tandem mounted twin motor vibrating conveyor moves a high temperature product a distance of 22 feet to a bucket elevator. The conveyor replaced a competitive leaf spring design that experienced constant downtime. |

Model TMC Twin Motor Vibrating Conveyors are available from 4' long to 18' long in flat pan or tubular trough construction. The units can be arranged for both base mounting and overhead suspension. The twin counter-rotating motors offer a semi-balanced conveyor design ideal for long transfer applications. Vibrating conveyor lengths longer than 18' are typically handled by series mounting of units in tandem. For example, a 30' system is made up of two (2) 15' units in tandem. Dust tight trough units with tray covers and flexible connectors are also offered. Other options include stainless construction, sight ports and scalping screen decks.

A variable speed controller is also avail-able for remote control. Power input to the vibrating motors is 230/460 volt, 3 phase, 60 cycle with other voltages and frequencies available on special order.

Final feed rate capacity is subject to trough's final design configuration and bulk product being conveyed.

Best Process Solutions, Inc.

1071 Industrial Parkway North

Brunswick, Ohio 44212

Phone: 330-220-1440 • Fax: 330-220-1447

© 2016. All rights reserved.