INSTALLATION FOR TWIN MOTOR VIBRATING FEEDERS

TMF Twin Motor Vibrating Feeders can be arranged for either suspension or base installation. Here are helpful considerations for proper installation and maximum feeding efficiency.

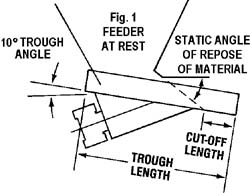

Figure 1

Vibrating Feeder trough

length is determined by the material's static angle of repose and trough slope.

The vibratingfeeder trough must be of sufficient length to assure complete material

shutoff when the feeder is at rest.

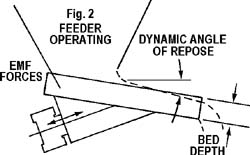

Figure 2

The dynamic angle

of repose is the angle the material seeks while being vibrated and

conveyed.

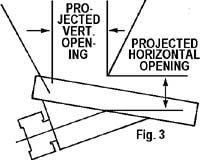

Figure 3

The projected

length and width of the vertical opening should be two to three times greater

than the largest particle dimension. Materials with bridging tendencies require

sufficient openings to assure good product flow. Caution should be exercised in

determining the vertical opening size to avoid excessive bin head-load on the

trough. The projected horizontal opening is determined by the particle size and

bed depth requirements to meet the design feed capacity. The minimum horizontal

opening should be approximately two times the largest particle dimension, but

not less than the bed depth required.

Best Process Solutions, Inc.

1071 Industrial Parkway North

Brunswick, Ohio 44212

Phone: 330-220-1440 • Fax: 330-220-1447

© 2016. All rights reserved.